C SERIES / CANTED COIL

ETS sells C Series or Canted Coil spring energized seals, which are commonly used in various applications involving reciprocating rods and pistons where there is a critical need to manage friction effectively. These seals are particularly beneficial in situations that require a wide tolerance range to ensure proper functioning. The unique C-shaped design of the seals is constructed from round wire stock, which is precisely coiled and expertly formed into a canted or slanted shape. This innovative design results in a radial compression spring characterized by a well-balanced flat load versus deflection curve, making it highly efficient in performance. The standard material utilized for these seals is 302 stainless steel; however, there are other optional sophisticated metals available to suit diverse operational needs. Additionally, multiple spring load options can be provided to meet specific requirements. With this information, you can be confident that you’ve found your premier seal supplier for all your sealing needs.

Features

• Canted Coil Spring with Flat Load vs Deflection

• Light, Medium and Heavy Load Springs Standard

• Standard Inch Fractional and MIL-G-5514 Sizes

• Standard 302 Series Stainless Steel Springs

• Hastelloy® Springs Available

• Temperature Range from -100° F to 450° F.

• Vacuum to 3000 psi Standard / 10,000 Extended

• Available as External & Internal Pressure Face Seals

Recommended Applications

• Reciprocating Rod and Piston Seals

• Rotary Shafts < 300 Surface Feet Per Minute

• Wide Tolerance and Misaligned Glands

• Friction Critical Applications

• Dynamic Applications below 450° F.

• Diameters <1/2” and Cross-Sections <3/32”

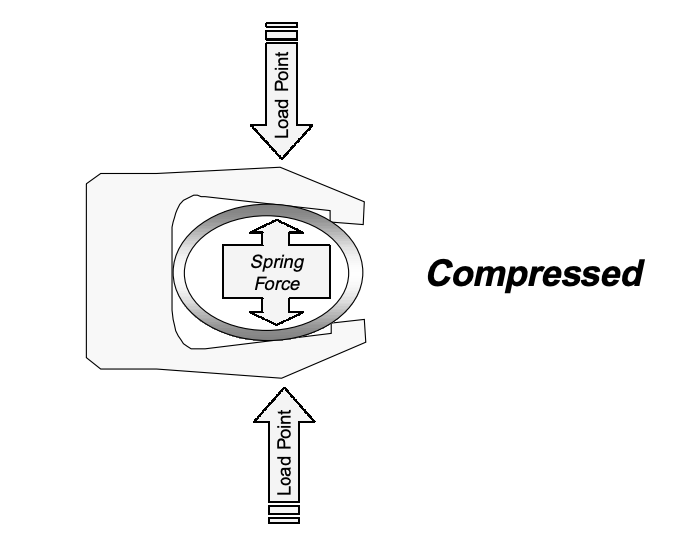

The canted-coil spring is intended for dynamic reciprocating and rotary applications. It is also used in static applications when wide gland tolerance or misalignment is present. The flat load curve of this design makes it an ideal choice for friction sensitive applications. The C Series spring can be fit into small seal diameters without overlapping the individual spring coils. Because the inside diameter coils tend to butt up to each other, the spring has very small gaps providing maximum spring contact. This geometry is well suited for dynamic rod seal applications that are less than 1/2” in diameter. The C Series spring produces compression load near the center of the seal. The standard beveled-lip seal geometry puts the point contact slightly in front, forcing the spring back into the spring cavity. The lip design provides concentrated unit load at the sealing interface, and allows lubrication to the dynamic lip, increasing the wear life. Because of this geometry, the C Series is not the best choice for abrasive medias. For abrasive conditions, the V Series is recommended. See page 9 for details. Compressed Canted Coil Spring / C Series Spring Force Load Point Load Point Individual coils provide the compression load to the sealing interface of the C Series spring. Because the rounded coils provide a point contact, the spring can imbed itself into the seal material at elevated temperatures. Applications above 450° F. should use the V Series for dynamic conditions or the H Series for static situations. The C Series spring is available in three load ranges; Light, Medium and Heavy. Light: Applications that require extremely low break-out and running friction when sealing ability is less important than friction. Medium: General application. Low friction but reliable sealing capability. Normally the starting point for new applications. Balance functions of friction, sealing ability and dynamic wear. Heavy: Generally static sealing applications only where optimum resilience is required due to hardware separation. Accelerated seal material wear in dynamic applications. Used when sealing is primary and friction and/or wear is second.